The Era of Textile Manufacturing During the British Industrial Revolution, from the late 18th to the mid-19th century, brought about an awesome change in textile production, improving society and the economy. The British Industrial Revolution emerged from traditional manual production methods to mechanized brilliance.

Key inventions like the flying shuttle, spinning jenny, water frame, and spinning mule revolutionised textile production. These innovations, such as John Kay’s flying shuttle in 1733, eased larger-scale errors and set the stage for further advancements.

Innovations & Visionaries

Inventors wanted to create machines that could spin multiple threads at once, making more things in less time. They put many machines in factories to save money and work better. People formed using machines rather than their hands to make more cash. The textile sector benefited from several innovations and innovative concepts during the Industrial Revolution. Some of the valuable inventions are:

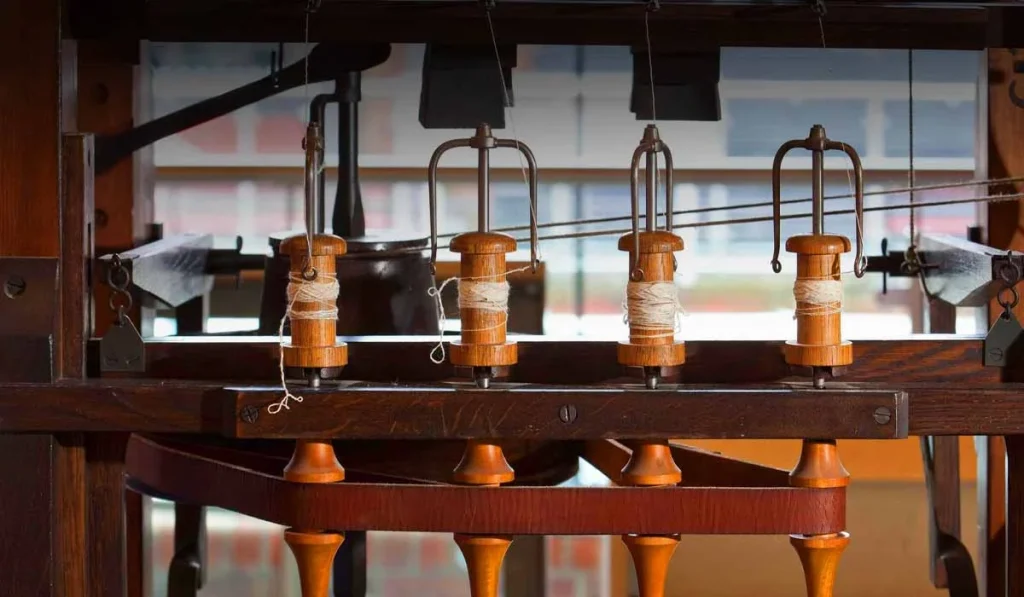

The Spinning Jenny

In 1764, James Hargreaves crafted the spinning jenny in Lancashire, a frame with multiple spindles, revolutionizing cotton spinning. It spun eight threads, later upgraded to 120, boosting production and cost-efficiency. 1788 Britain had 20,000 jennies in factories, supplanting isolated cottage industries, thanks to water wheel power.

The Water Frame

In 1769, Richard Arkwright (1732–1792) conceived the water frame. John Kay, who was a clockmaker and a friend of Richard Awkwright, helped him in this invention. They replaced levers with gears, improving efficiency. The water frame’s design benefited from Britain’s watchmaking expertise, concentrated in Lancashire, where textile machinery emerged.

The Spinning Mule

In 1779, Samuel Crompton created the spinning mule by merging Hargreaves’ Jenny and Arkwright’s water frame. It produced finer yarn and increased spindles. Operating at 46 meters required three workers, but its triumph led to steam-powered versions. Lancashire had factories with 60 machines, totaling 50 million mule spindles.

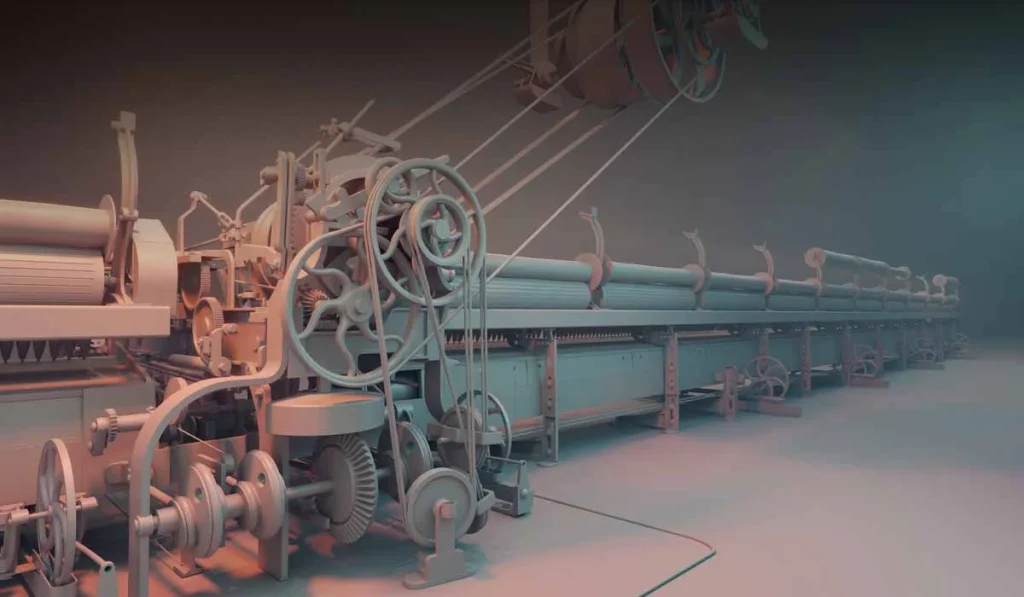

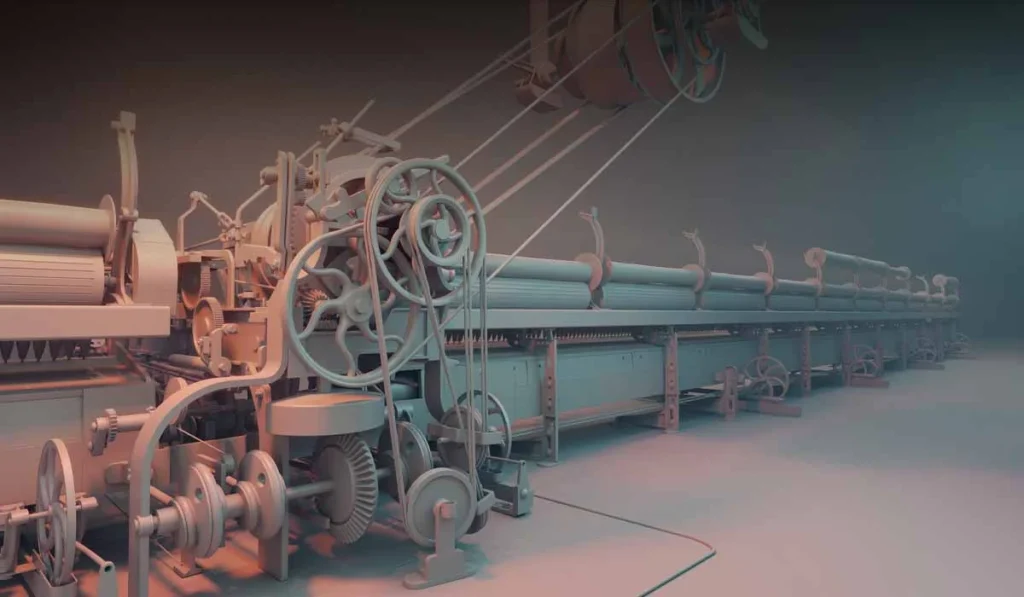

The Power Loom

After seeing a factory, Edmund Cartwright (1743-1823), a former clergyman, invented the power loom in 1785. It needed one worker to change spindles every seven minutes. Despite initial flaws, it doubled cloth production speed, inspiring later improvements. Used by Richard Arkwright, factories adopted it widely, earning Cartwright recognition and a Royal Society Fellowship in 1821.

The Cotton Gin

Eli Whitney (1765-1825) invented the Cotton Gin in 1794, using revolving teeth to remove cotton seeds efficiently. It processed 25 kg (55 lbs) daily, boosting cotton production. Widely copied, Whitney gained little profit despite patent registration. Cotton’s surge led to increased slave labor on plantations. By 1830, cotton comprised 55% of British imports and half of its exports

The Roberts’ Loom

Richard Roberts (1789-1864) invented the steam-powered cast-iron loom in 1822. Iron construction prevented warping, ensuring yarn tension. Fewer yarn breakages sped up cloth production. Constant improvements spread globally, with machines even smuggled to other countries. Increased efficiency made machines profitable worldwide, surpassing labor cost differences.

The Self-Acting Mule

In 1825, Richard Roberts designed a self-acting spinning machine to complement his loom. High demand for weavers’ yarns push this innovation. The machine’s gears, cranks, and guide mechanism ensured continuous, precise operation, reducing human involvement. Roberts’ inventions aligned with factory owners’ goal of minimizing human labor.

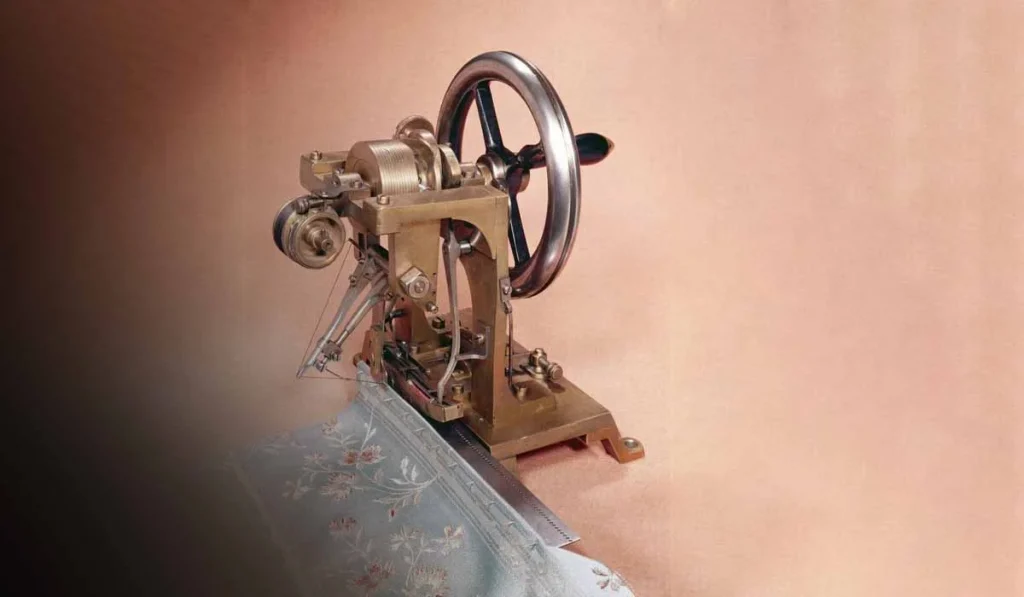

Howe Sewing Machine

Elias Howe (1819-1867) created a new sewing machine in 1844 (patented 1846) featuring the lockstitch for added strength. It outpaced hand sewing with 640 stitches per minute versus 23. Isaac Singer’s company, with royalties to Howe, became a sewing machine leader, selling half a million yearly by 1870.

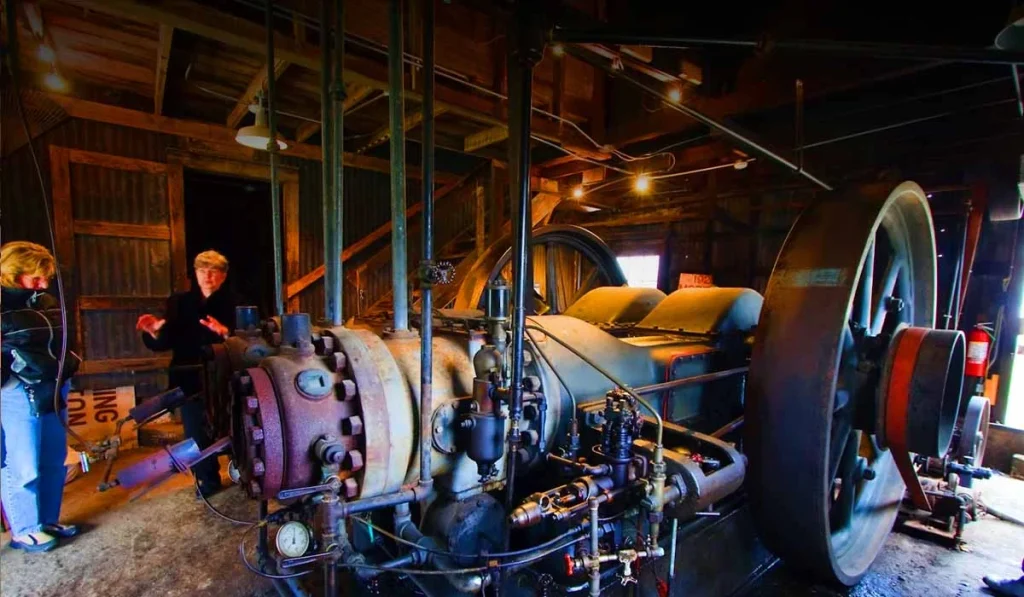

Role of Steam Engines

The integration of steam engines, notably James Watt’s 1775 invention, powered factories, and mills, significantly boosting productivity. Steam engines propelled areas lacking water resources into the industrial age. They amplified the impact of Textile Manufacturing During the British Industrial Revolution.

Societal Transformation & Challenges

This era triggered profound societal changes. Centralized production led to rapid urbanization, reshaping communities and labor dynamics. However, challenges emerged, including grueling working conditions and low wages. Movements advocating labor reform and improved standards gained momentum in response.

Global Influence

The impact of Textile Manufacturing During the British Industrial Revolution extended globally. Samuel Slater’s journey to the United States disseminated British textile technology and initiated an industrial era across the Atlantic. The Morozov family harnessed the revolution’s potential in Russia, establishing a thriving textile enterprise.

Legacy & Tradition

Textile Manufacturing During the British Industrial Revolution epitomizes the fusion of innovation, machinery, and societal evolution. This shift from cottage industries to mechanized factories fueled by steam engines left an indelible mark on society and the economy.

Beyond its historical significance, it is a timeless reminder of the intricate interplay between technological advancement and the human experience.

Expansion of The Revolution

The impact of Textile Manufacturing During the British Industrial Revolution rippled far beyond the realm of textiles. The mechanization and technological breakthroughs witnessed in textile production paved the way for advancements in other industries.

The principles of automation, centralization, and the utilization of machinery laid the foundation for modern manufacturing practices. The factories that emerged as a result of this revolution set a precedent for the organization of production processes, influencing industries such as iron, coal, and transportation.

Economic Transformation

The revolution in textile manufacturing had profound economic implications. The increased efficiency and scale of production drove down costs, making textiles more accessible to a broader population.

This affordability, coupled with the expansion of global trade, resulted in textiles produced during the British Industrial Revolution becoming sought-after commodities worldwide. The economic prosperity generated by the textile industry laid the groundwork for further industrialization and the rise of capitalism.

Social & Cultural Shifts

The societal changes brought about by the revolution were not confined to the workplace. Urbanization, driven by the concentration of factories and opportunities in industrial towns, reshaped demographics and living conditions. The inrush of people into metropolitan areas forced a new social ranking and the emergence of the working class.

This period also witnessed cultural shifts as traditional methods gave way to modern, mechanized processes, impacting art, literature, and daily life.

Environmental Impact

While the revolution propelled innovation and progress, it also had environmental consequences. The need for raw products like cotton fueled colonialism and the exploitation of help in far-off regions.

Additionally, the rapid growth of factories led to increased pollution and environmental degradation, laying the groundwork for future discussions on sustainability and responsible industrial practices.

Conclusion

Textile Manufacturing During the British Industrial Revolution stands as a testament to the remarkable power of innovation to reshape society, the economy, and the course of history. The excellent blend of machinery, technology, and human ability brought about a revolution that transformed the bounds of the textile industry.

Its impact reappeared globally, affecting different aspects of life and setting the stage for a new era of industrialization and progress. As we think about this critical period, we are reminded of the high-tech teamwork between human desire, technological advancement, and the complex array of social revolution.